Toll Manufacturing

Besides the commercial portfolio of catalyst supports, that we offer, Exacer is also an experienced partner for your toll manufacturing projects.

You can talk with experts: Our team has a long experience in the catalyst field. This helps us to get quickly to the point that our customers need. Feel free to ask us for advice, and we will also do our best to drive your particular project with our own ideas to a final success story!

Your data are in trustworthy hands: Exacer has an independent position on the market and is not controlled by any major raw material supplier or catalyst producer. Furthermore, as a fundamental business rule, Exacer is not selling any commercial catalysts to the market, as we do not want to become a competitor to our customers. As a technology-driven company, we like to talk about technical details with your experts. This is a prerequisite to understand the exact needs of our customers and to finally end up with the best solution. Such an intimate discussion requires a discrete treatment of sensitive information. Feel free to ask us for a non-disclosure agreement to cover your project ideas!

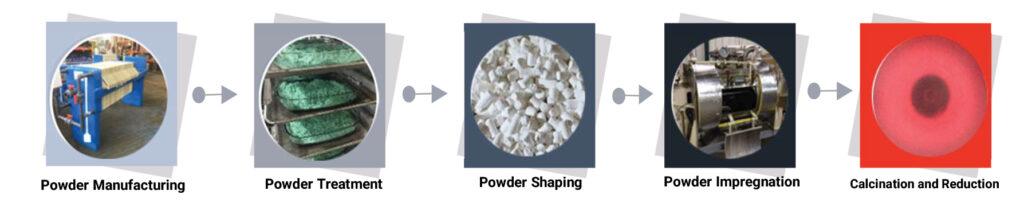

Beyond shaping – Toll manufacturing of full catalyst recipes: Exacer can do more than just shape a powder. Together with selected partners Exacer is capable of producing a full catalyst recipe including powder precipitation, powder impregnation, milling steps, impregnation of carrier bodies or even reduction steps for a final activation. All our partners are quality companies from Europe or the US, which are typically specialized on their particular unit operations and not competing with our customers. The advantage for our customers is that Exacer, due to its deep understanding of catalyst manufacturing and applications, can drive such a complex production chain as a main contact in a successful and efficient way and the customer does not have the pain of managing several partners for one project in parallel. As Exacer, also many of our partners have developed highly skilled solutions for particular steps – we may also be able to convey new solutions to our customers, that you did not consider before.

Developmental support: Exacer is open for all types of projects – from a precise transfer of your own recipe to our machines up to a joint development or anything in between these extremes is feasible. Moreover, Exacer also offers support for scale-up activities, such as trials or recipe development in kilogram scale and under full scalable conditions. If you do not have such capabilities in-house or they are overbooked, please do not hesitate to ask us for support in your specific project!

Production networks

Established partnerships with trustful and reliable companies in Europe and the US enable Exacer to manage a complete production chain of a custom catalyst. We will transparently share which steps are outsourced and our customers will receive the final product and all services from one company. All partnerships are covered by secrecy contracts and do typically not involve major catalyst producers, but rather preferably small companies, specialized on single unit operations.

Range of Available Unit Operations

• Tableting

• Calcining

• Precipitation / Powder Handling*

• Powder Impregnation / Dry Impregnation under Vacuum and Temperature*

• Reduction*

*) in cooperation with partner companies